Professional Lift Maintenance Contractors for Resilient Performance

Wiki Article

Proficient Lift Engineer Offering Accuracy Repair Service Methods for Elevators in Industrial Facilities

Elevator Repair Proficiency

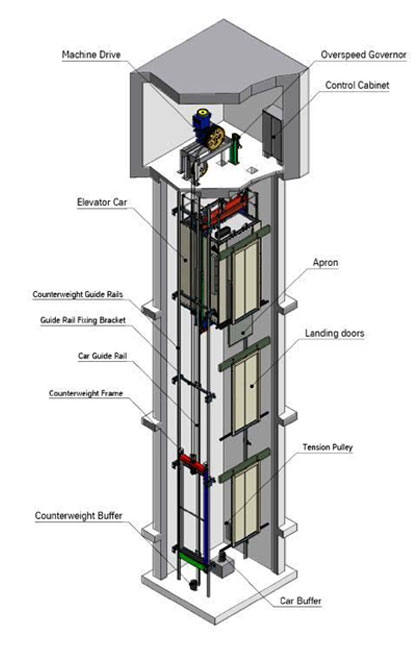

In the realm of lift repair work experience, a comprehensive understanding of electric parts and mechanical systems is paramount for efficient fixing and maintenance. Elevator repair work specialists must have a deep understanding of exactly how these elaborate systems function together to make certain the reputable and safe operation of elevators in commercial facilities. Mechanical systems incorporate important components such as raising systems, pulleys, and safety and security tools, all of which need to work harmoniously to carry individuals and goods with accuracy and safety. Comprehending the electric elements entails knowledge of electric motor controls, wiring, and sensing units that manage the elevator's motion and guarantee correct performance.Furthermore, lift repair service experts need to be adept at detecting issues promptly and accurately to reduce downtime and avoid possible security hazards. They have to possess the skills to interpret technological schematics, make use of analysis devices efficiently, and apply suitable fixing methods. By remaining abreast of industry innovations and adhering to safety policies, elevator repair service technicians can provide reputable and reliable repair service services that support the operational quality of commercial elevators.

Accuracy Strategies for Maintenance

Attracting on their proficiency in electric elements and mechanical systems, elevator repair service professionals implement precision techniques for upkeep to ensure the continued risk-free and trustworthy procedure of industrial lifts. These proficient specialists depend on a systematic approach that consists of regular inspections, lubrication of relocating components, change of stress in cable televisions, and substitute of damaged components. By adhering to supplier guidelines and sector criteria, lift technicians can find potential concerns early and prevent expensive breakdowns.One important accuracy maintenance method is making use of resonance analysis devices to monitor the condition of elevator motors and bearings. By analyzing vibration patterns, technicians can identify abnormalities that might suggest approaching failing, allowing them to take proactive actions prior to a failure takes place. In addition, precision alignment of lift shafts and pulleys is vital to lessen deterioration on parts and make sure smooth procedure.

Incorporating these accuracy maintenance techniques right into a normal lift upkeep routine assists prolong the lifespan of industrial elevators, lower downtime, and boost total safety and security in industrial facilities. - repair and maintenance services

Industrial Facility Solutions

Utilizing strategic methods and ingenious innovations, commercial center remedies use detailed approaches for optimizing operational effectiveness and optimizing productivity. Industrial centers need customized remedies to resolve the one-of-a-kind challenges they deal with, such as intricate equipment, heavy equipment, and strict safety and security laws. These remedies incorporate a variety of services including center format design, tools maintenance programs, power efficiency improvements, and workflow optimization.One secret facet of industrial facility options is anticipating maintenance, which uses data analytics and sensing units to monitor tools efficiency in real-time. By recognizing potential issues before they escalate, downtime is lessened, and operational disruptions are reduced. In addition, implementing lean production concepts can simplify manufacturing processes, eliminate waste, and enhance overall effectiveness.

Additionally, commercial center options often include the assimilation of automation systems to increase productivity and guarantee consistent output quality. Automated processes can manage repeated jobs with precision and rate, permitting employees to concentrate on more complex procedures. On the whole, these solutions are vital for modern industrial facilities aiming to stay affordable in a vibrant market setting.

Troubleshooting and Innovation

Industrial center remedies lead the way for dealing with operational challenges efficiently, with troubleshooting and innovation playing an essential duty in boosting upkeep techniques and technical advancements within commercial settings. The capability to repair issues quickly and properly is extremely important to make certain very little downtime and ideal efficiency when it comes to lifts in commercial centers. Skilled lift engineers other are geared up with the proficiency to identify issues without delay, making use of innovative methods to fix problems with precision.Innovation in elevator repair work within industrial facilities entails the integration of advanced modern technologies such as IoT sensors for more tips here anticipating upkeep, remote surveillance systems, and information analytics for efficiency optimization. By leveraging these innovative services, lift engineers can proactively identify prospective problems before they escalate, causing cost financial savings and enhanced functional efficiency.

Moreover, fixing techniques incorporate an organized method to diagnosing elevator malfunctions, consisting of assessing error codes, examining mechanical components, and conducting performance examinations. By integrating troubleshooting methodologies with ingenious repair work methods, lift designers can provide top notch maintenance services that ensure the smooth procedure of elevators in commercial centers.

Smooth Lift Workflow

Reliable elevator procedures are necessary for guaranteeing smooth and undisturbed operations within industrial facilities. Lift service technicians play an important role in making sure that elevators are functioning optimally at all times. By prioritizing seamless lift operations, commercial facilities can boost safety and security, optimize logistics, and create a conducive environment for employees to carry out their jobs efficiently.Verdict

To conclude, the experienced lift designer uses precision fixing techniques for lifts in industrial facilities, ensuring seamless procedures and efficient upkeep. Their proficiency in troubleshooting and innovative solutions contribute to the smooth functioning of elevators in these settings. With a concentrate on precision techniques, the engineer supplies useful solutions to commercial facilities, permitting for secure and reputable elevator operations.Lift repair work service technicians need to possess a deep understanding of exactly how these intricate systems function with each other to ensure the secure and reputable procedure of lifts in industrial facilities. By remaining abreast of industry advancements and adhering to security laws, lift repair service service technicians can provide effective and reliable repair solutions that promote the functional quality of commercial elevators.

Drawing on their competence in mechanical systems and electric elements, elevator fixing specialists execute precision methods for maintenance to make sure the continued secure and reliable procedure of industrial lifts. Lift specialists play a vital function in ensuring that lifts are working optimally at discover here all times.In final thought, the skilled lift engineer provides accuracy repair service strategies for lifts in commercial facilities, ensuring seamless procedures and reliable maintenance.

Report this wiki page